Actuating unit for electric panel

Actuating unit for outdoor use

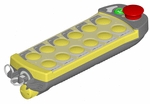

Bravo 6-8 Industrial radio remote control

Bravo 8 Display Industrial radio remote control

SPECIFICATIONS

Programming via radio interface (optional).

Bravo Interface programming software (for Windows 98/ME/2K/XP and Pocket PC).

Two-way transmission with automatic selection of the best channel.

Passive or active Display module for visualising or questioning the data coming from the Actuating Unit or Echo.

Further information available on the technical documentation PRCA0EAP00.

TECHNICAL CHARACTERISTICS

Operational temperature -25°C / +70°C

Degree of protection IP 65

Weight 420 g

Range 200 m max.

Battery life 40 h

Safety category 3 (EN 954-1)

4 (EN 954-1 stop function)

Markings and conformity CE, 89/392/CEE, 73/23/CEE, 89/336/CEE,

99/05/CEE

DESCRIPTION

ATTENTION! This product is sold together with the Actuating Unit.

Radio remote controls require no wiring between the control station and the machine, and thus give the operator freedom of movement withing their range. This optimizes the control and accuracy of operations, limiting the risk of accidents and increasing productivity and efficiency.

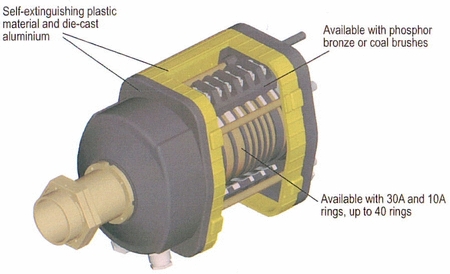

Bravo is a radio remote control system for industrial machines, composed of a control station and a modular actuating unit that is directly connected to the machine to be controlled. Due to the modular construction of the actuating unit, Bravo can easily be adapted to meet different needs, depending on the type and characteristics of the machine.

The control station transmits the control signals from the machine to the actuating unit, which enables the associated functions via the relays.

The actuating unit is designed for easy installation inside an electrical panel by means of an Omega bar (DIN EN 50022). However, the radio remote control can also be installed inside an outdoor box (IP55), so that it can be used on any type of machine.

Bravo features a high degree of customisation, so that it can easily adapt to special devices that deviate from the standard available on the market.

The distinctive innovations of the radio remote control are the results of over 4 years of study and research by our mechanical, electronic and computer engineers, involving the science of materials, the most advanced technology for numerical simulation and the new electronic technologies.

This process has resulted in a control station featuring very high resistance and endurance in the heavy duty industrial environment.

The peculiar design of the product ensures great ergonomics and excellent protection against accidental impact to the normally exposed parts.

The accumulators, batteries and battery charger are standard parts easy to find on the market.

The Bravo project has been developed using the most modern signal processing technologies, integrating the hardware components as to reduce their number, and making extensive use of elements dynamically programmable by the system. The result is an extremely versatile system, capable of adapting simply and rapidly to different uses, so that the installer and user only have to deal with the basic installation and use operations. The countless technological innovations of the Bravo system are absolutely transparent and the advantages are evident, while no complex activating and programming procedures are required. The few settings that have to be made are those required to customise the radio remote control and they are carried out in a simple and intuitive way, without need for special programming knowledge. You only need to know what the radio remote control is supposed to do: the Bravo Interface programming software will guide the installer simply through the necessary settings, automatically adjusting all the technological resources that Bravo incorporates.

More Info PriceBravo10-12 Industrial radio remote control

Bravo4 Industrial radio remote control

Delta Industrial radio remote control